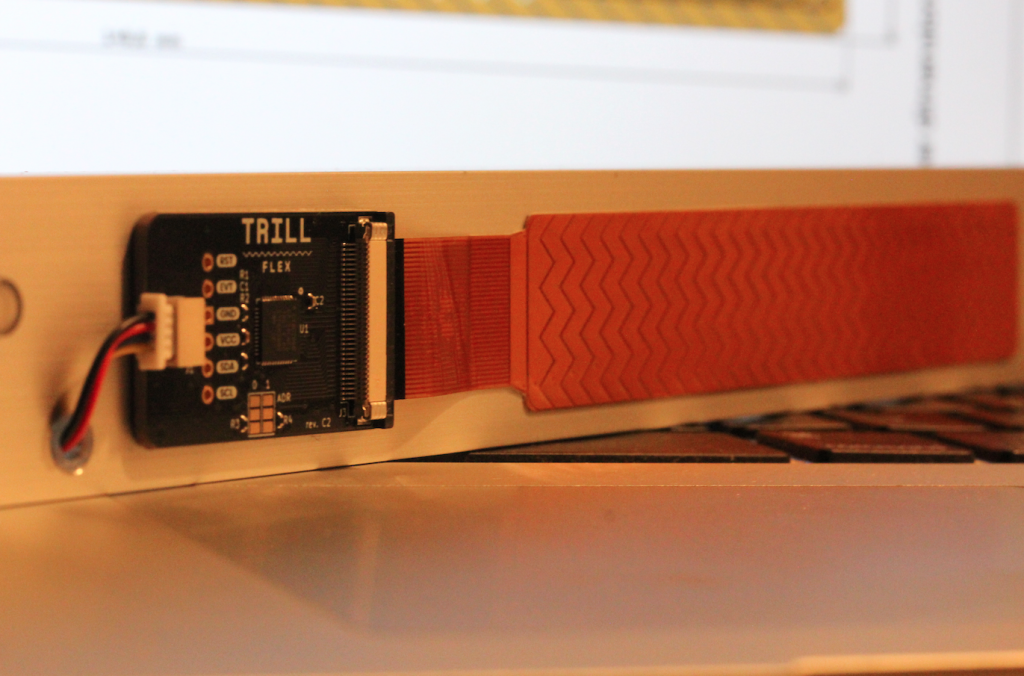

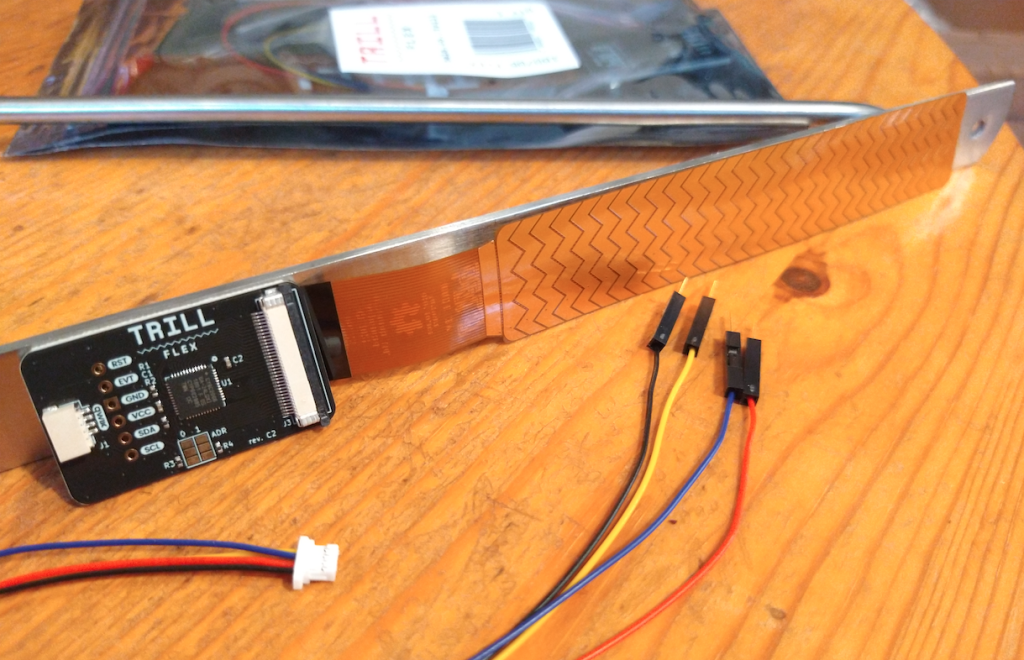

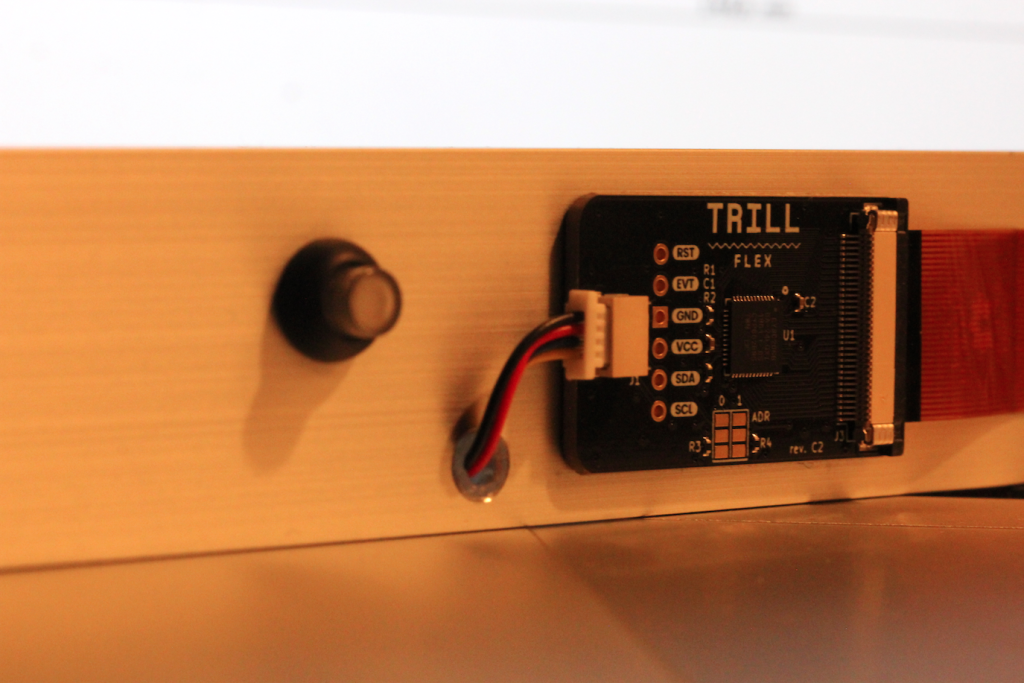

Unfortunately, the width of the Trill Flex sensor protrudes from the base. I will have to manufacture the exterior using channel material of the width of the sensor to cover the base, but it seems difficult to obtain channel material with an inside diameter of 20 mm exactly. There is a way to procure a 1-inch wide material, but this too would be difficult in Japan.

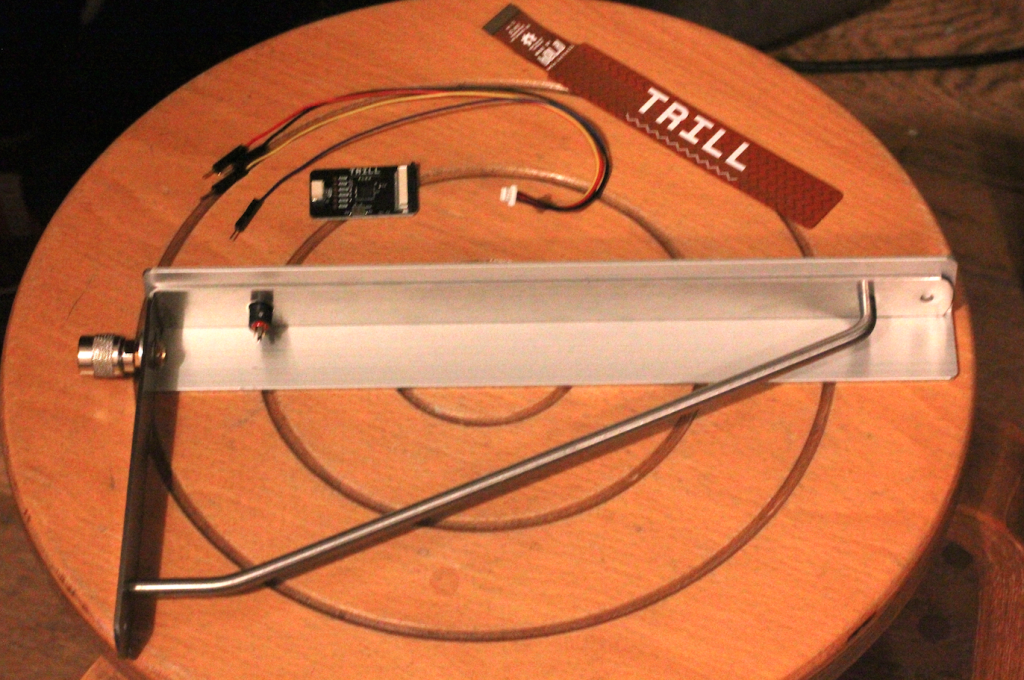

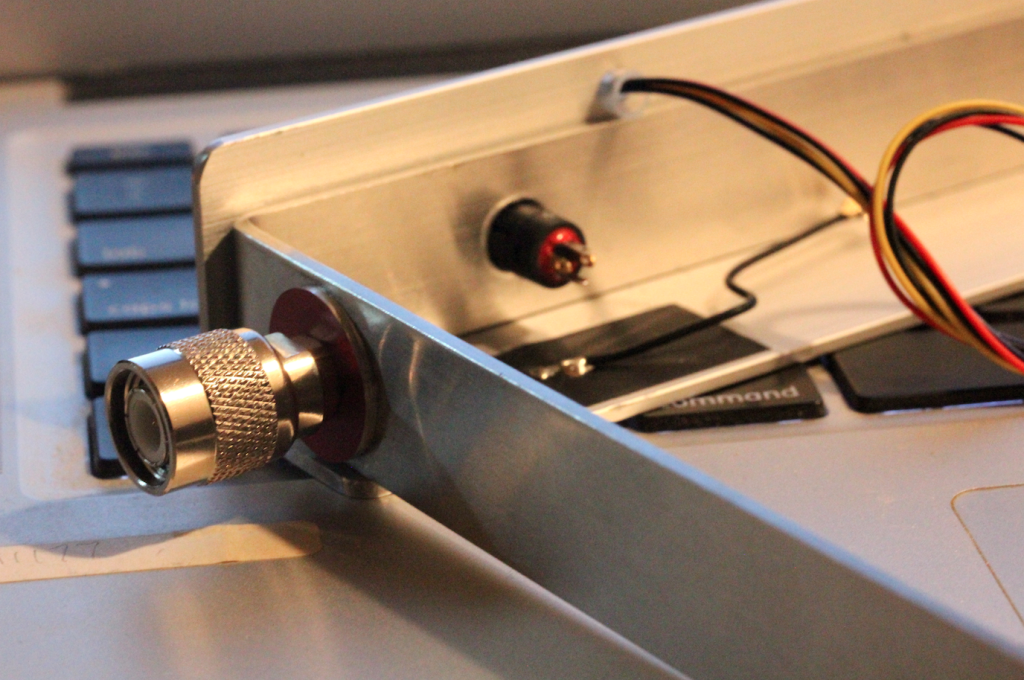

If you cannot find a suitable material, it is more realistic to use a simple angle material as a base for the MCU and battery, which will reduce the difficulty of the construction.

The problem is the “look” of the barracks wiring, but this may be satisfactory depending on the design.

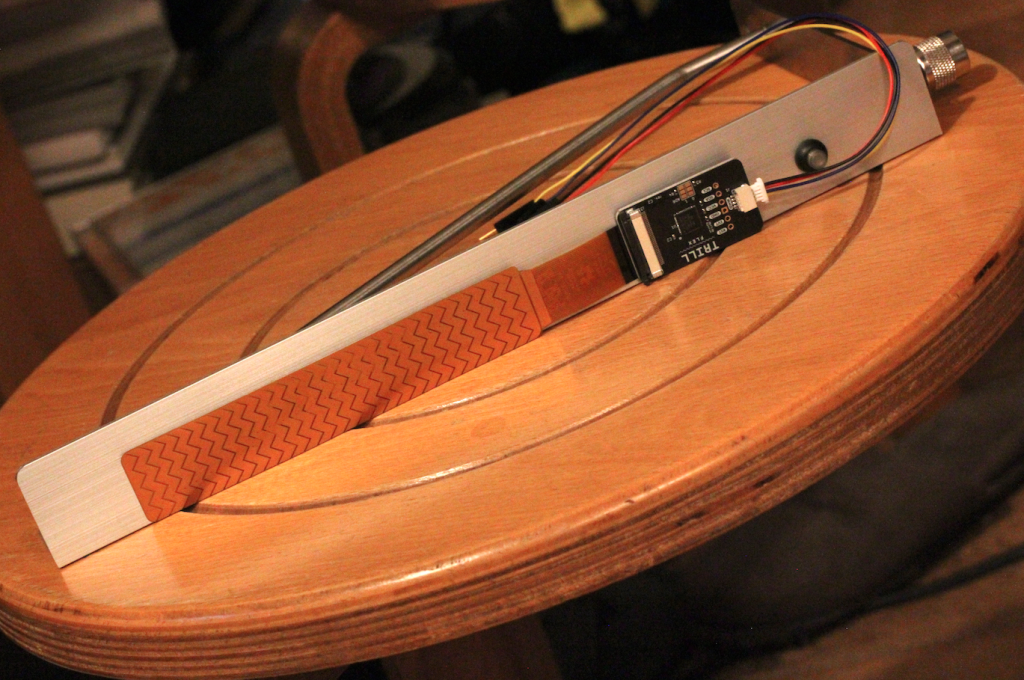

The corresponding pitch range of the sensor will be switched from 2oct. to 5oct. using a push switch.

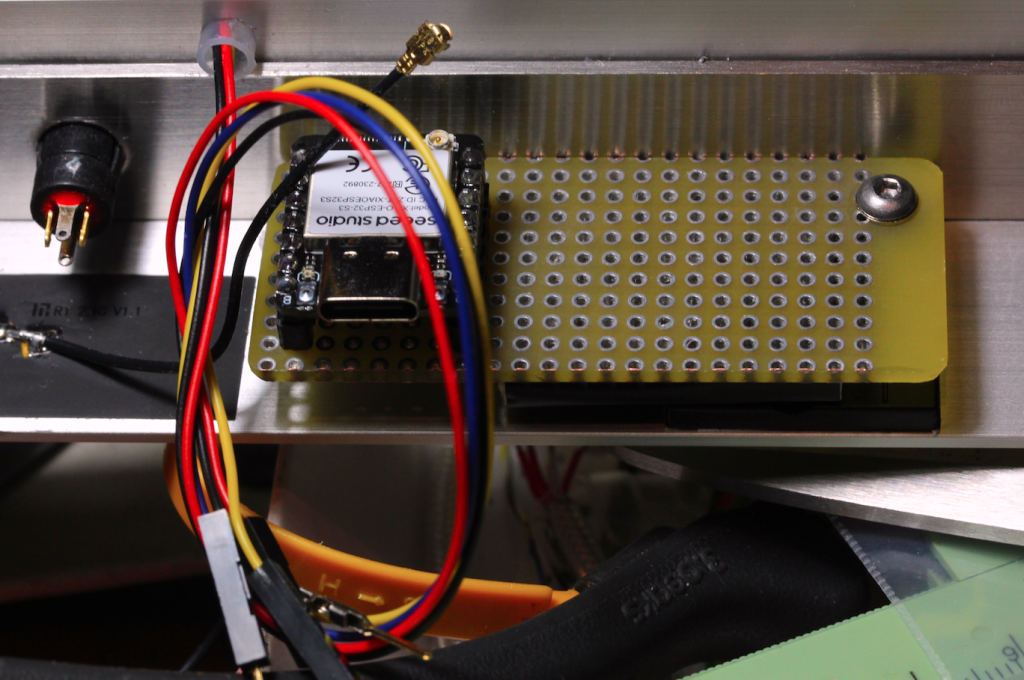

XIAO/ESP32-S3 and battery are mounted on the back side. The black tape is the antenna of the ESP32.

Double-sided tape was used to secure the heat sink to the sensor/device. This ensures safety even during the extremely hot summer months.